Download Data Sheet

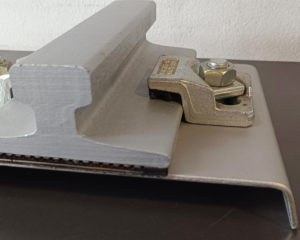

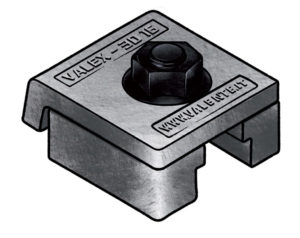

VALEX-3016

FEATURES

• Fastening system for rails with or without pad.

• System made up of two interlocked elements, which allow easy clip lateral adjustment.

• System components locked together by bolt and flanged nut.

• System lower element easily weldable to rail support.

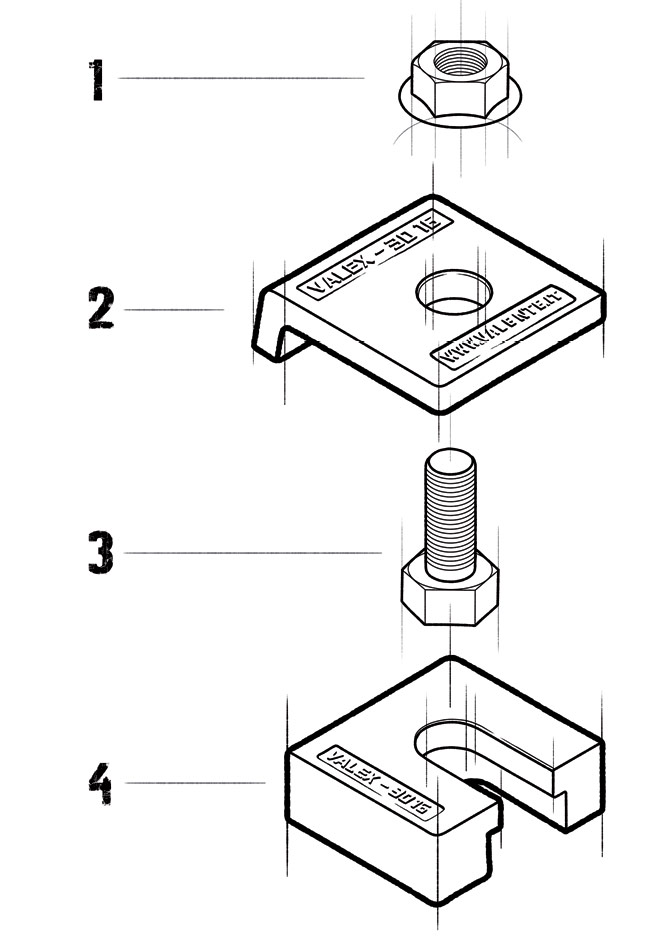

COMPONENTS PROVIDED

• Flanged nuts M 16

• Upper clip with steel nose.

• Special screws M 16

• Weldable lower clip

Developed for crane rails, VALEX 3016 indirect fastening system is used, with excellent results, also with train and light rails. A very rugged, reliable, contained dimensions fastening system, used with any type of crane independently of driving system.

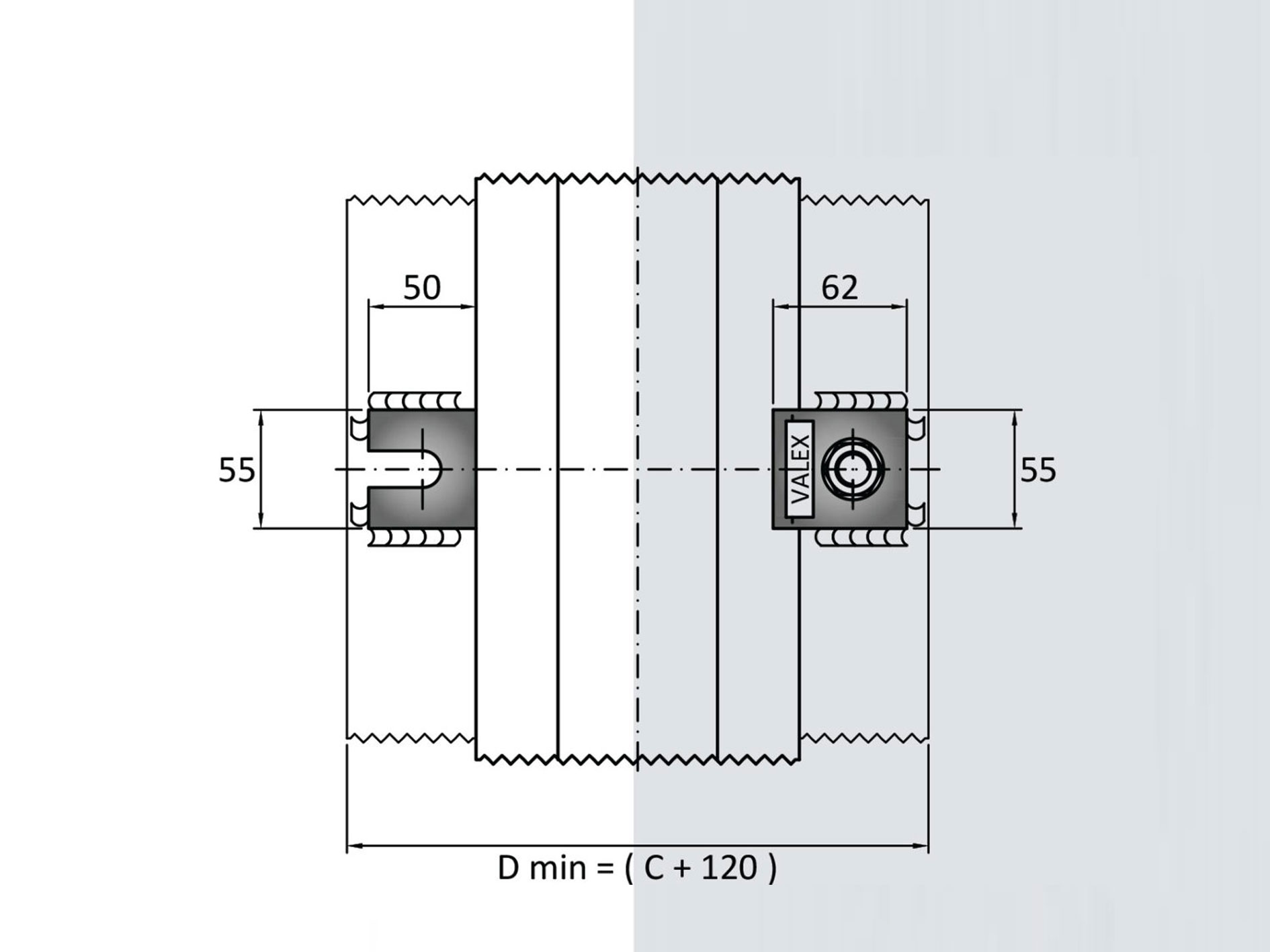

| Dimensions [mm] | E | F | G | H | L | L1 | L2 | M | N | O | P | Weight [g] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VALEX 3016-28-9 | - | - | - | 9 | - | - | - | - | - | - | - | 670 |

| VALEX 3016-28-12 | - | - | - | 12 | - | - | - | - | - | - | - | 680 |

| VALEX 3016-28-15 | - | - | - | 15 | - | - | - | - | - | - | - | 680 |

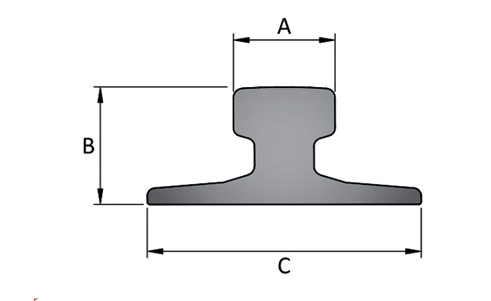

| Rail Type | A [mm] | B [mm] | C [mm] | Weight [kg/m] | Without Pad | With Pad |

|---|---|---|---|---|---|---|

| A 45 | 45 | 55 | 125 | 22,1 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| A 55 | 55 | 65 | 150 | 31,8 | VALEX 3016-28-15 | - |

| A 65 | 65 | 75 | 175 | 43,1 | VALEX 3016-28-12 | - |

| A 75 | 75 | 85 | 200 | 56,2 | VALEX 3016-28-12 | - |

| A 100 | 100 | 95 | 200 | 74,3 | VALEX 3016-28-12 | - |

| A 120 | 120 | 105 | 220 | 100 | VALEX 3016-28-09 | - |

| A 150 | 150 | 150 | 220 | 150,3 | - | - |

| CR 104 | 63,5 | 127 | 127 | 51,59 | VALEX 3016-28-09 | - |

| CR 105 | 65,1 | 131,8 | 131,8 | 52,09 | VALEX 3016-28-12 | - |

| CR 135 | 76,2 | 146 | 131,8 | 66,97 | VALEX 3016-28-09 | - |

| CR 171 | 101,6 | 152,4 | 152,4 | 84,83 | - | - |

| MRS 87 A | 101,6 | 152,4 | 152,4 | 86,8 | - | - |

| CR 175 | 102,4 | 152,4 | 152,4 | 86,8 | VALEX 3016-28-09 | - |

| MRS 125 | 120 | 180 | 180 | 125 | - | - |

| S 7 | 25 | 65 | 50 | 6,75 | - | - |

| S 10 | 32 | 70 | 58 | 10 | - | - |

| S 14 | 38 | 80 | 70 | 14 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| S 18 | 43 | 93 | 82 | 18,3 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| S 20 | 44 | 100 | 82 | 19,8 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| S 24 | 53 | 115 | 90 | 24,43 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| 25 kg/m | 50 | 115 | 90 | 25 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| S 26 (AFNOR 26) | 50 | 110 | 100 | 26,27 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| 27 E1 (27 UNI) | 50 | 120 | 95 | 27,06 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| AFNOR 30 | 56 | 125,5 | 106 | 29,98 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| 30 E1 (S 30) | 60,3 | 108 | 108 | 30,13 | VALEX 3016-28-15 | VALEX 3016-28-09 |

| 33 E1 (S 33) | 58 | 134 | 105 | 33,47 | VALEX 3016-28-12 | - |

| 36 E1 (36 UNI) | 60 | 130 | 100 | 36,26 | VALEX 3016-28-12 | - |

| 40 E1 (S 41-R14) | 67 | 138 | 125 | 40,95 | VALEX 3016-28-12 | - |

| 46 E4 (46 UNI) | 65 | 145 | 135 | 46,9 | VALEX 3016-28-12 | - |

| 49 E1 (S 49) | 67 | 149 | 125 | 49,39 | VALEX 3016-28-12 | - |

| 50 E5 (50 UNI) | 67 | 148 | 135 | 49,9 | VALEX 3016-28-12 | - |

| 54 E1 (UIC 54) | 70 | 159 | 140 | 54,77 | VALEX 3016-28-12 | - |

| 60 E1 (UIC 60) | 72 | 172 | 150 | 60,21 | VALEX 3016-28-09 | - |

GENERAL INSTRUCTIONS

The selection of a fastening system is a critical, important decision both when placing a track or a single rail. The wrong selection could have expensive consequences and create serious problems such as:

• Slow down or shut down of the production process.

• Excessive and, or irregular wear of rails.

• Damage of mechanical components of crane.

• Damage to supporting base.

• Damage to fastening system.

VALEX fastening systems have been developed building on the experience accumulated over more than 100 years of activity

VALENTE fastening systems offer an unlimited selection of alternatives, which perform in the most effective and efficient way in every situation..

ASSEMBLING INSTRUCTIONS

• Place the lower clip facing the rail according to the drawing at the distance indicated in the technical card.

• Weld the two perpendicular sides and the diagonal side of the lower clip opposite to the rail with either electrode or rode.

• Insert the screw in the lower clip.

• Place upper clip and the flanged nut.

• Proceed to a light tightening.

• Control line up of the rail.

• Complete tightening

ELECTRODES

• AWS A5.1-04 E7018-1

• EN ISO 2560-A E42 4 B42 H5

• CE EN 13479

ROD

• AWS A5.18 ER 705-6: SG3

• EN ISO 1668 W 4Si1: SG3

TECHNICAL SPECIFICATIONS

• Side load 65 kN

• Torque tightening 175 Nm

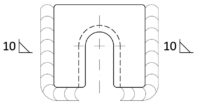

• Welding seam thickness 10 mm (see technical drawing below)

• Bolt M16 8.8 gr

• Steel quality S355JR